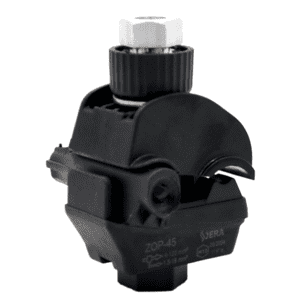

We use ISO 9001 standard for our daily working process. In technology operations we apply testing criteria from different international area standard testing scopes. Such as EN-50483:4, NF C 33 020, NF C 33 041, IEC 61238-1, IEC 60099-4:2014 and others. We have on site laboratory and proceed quality inspection. We cooperate with many of 3rd parties bodies, and specifically accredited according to ISO/IEC 17025:2018 laboratories which are qualified to conduct the related tests and issue the testing reports and certificates. Jera Line produce products in accordance to the international standards of power cable products. And consider testing activity as crucial for area of our business scope. We do cooperate with local common quality inspection authorities, such as SGS, Bureauveritas. We operate globally with some countries and regions, and acknowledge each market request and standard, to make our products be more suitable for specific market request. Jera Line can customize the product per you standard request. Welcome to contact us for more details.

Jera Line' s on-site testing laboratory with different types of equipment, may perform the related quality tests of power cable connectors within the international testing scopes. We are capable to maintain testing of our products within the following areas: Electrical performance validation Environmental performance validation Mechanical properties & performance validation Chemical Composition Analysis & validation Jera Line lab equipment set was combined in accordance to the routine and type testing scopes mention in the international testing standard of EN-50483:4, NF C 33 020, NF C 33 041, IEC 61238-1, IEC 60099-4:2014 and others. In addition we cooperate with many of 3rd parties bodies, and specifically accredited according to ISO/IEC 17025:2018 which are qualified to conduct the related tests and issue the testing certificates. Jera Line manufacture the power cable products in accordance to the international quality standards of power cable area. And consider testing activity as crucial for area of our business scope.

Our quality control process is designed as the combination of the international standard for power connectors and the production with given level of technology, personnel experience, and the possible testing scopes. We eager to find the problem with quality within the technology process, but not with the ready products. We do follow to common criteria of Raw material quality control, Semi-finished products quality control, and Finished products quality control. At the stages of products finishing, as well as at the levels of personnel responsibility. We do use digital system to appoint and track the exact values of control of production process. With the evaluation of control points by exact team members. We also work with suppliers of raw materials to conduct the related test within their production technology but not at our warehouse. Welcome to contact us in case of any quality issues, we consider each issue to make the product better.