In the world of electrical power distribution, ensuring reliable and efficient connections is paramount. Cable lugs with shear head bolts have become a staple in medium-voltage applications like 1-11kV power lines. These components offer a number of advantages that make them an ideal choice for power distribution systems. From ease of installation to long-term durability, let's explore why cable lugs with shear head bolts are so widely used and how they can benefit your electrical projects.

Before diving into the benefits, it's important to understand what cable lugs with shear head bolts are. A cable lug is a connector used to attach a wire or cable to a terminal or busbar. The lug provides a secure connection, ensuring that electrical current flows smoothly and reliably.

Shear head bolts are a specific type of bolt used to fasten cable lugs to the cables or terminals. These bolts are designed with a unique head that shears off once the bolt has been tightened to a pre-determined torque value. This ensures that the correct pressure is applied to the connection without over-tightening, making the installation process more efficient and reliable.

1. Cable Lug: Typically made of copper, aluminum, or tinned copper, designed to handle electrical connections safely and effectively.

2. Shear Head Bolt: A bolt designed to break off at a specific torque level, ensuring proper tightening without over-torquing.

One of the primary reasons cable lugs with shear head bolts are favored is their ability to deliver a consistent and secure connection. The shear head bolt ensures that the correct amount of torque is applied, which means the connection will be tight enough to prevent loose contacts but not so tight that it risks damaging the cable or terminal. This consistency significantly reduces the risk of electrical faults, such as overheating or arcing, which can occur when connections are improperly tightened.

Moreover, these connections are low-resistance, ensuring minimal energy loss and optimal electrical performance, especially critical in medium-voltage power lines like those operating at 1-11kV.

The shear head bolt design makes installation easier and faster compared to traditional methods that rely on manual torque measurement. Here's how it simplifies the process:

● No Need for Torque Wrenches: Unlike conventional bolted connections that require precise torque measurements, shear head bolts automatically break off when the correct torque is reached. This eliminates the need for a torque wrench and reduces installation time.

● Quick and Simple: Installation is as simple as tightening the bolt until the head shears off, ensuring that workers can quickly move on to the next connection, improving overall project efficiency.

The simplicity of installation reduces labor costs and makes it easier for technicians to work in challenging environments, such as remote locations or places with limited tools.

Once installed, cable lugs with shear head bolts are maintenance-free, making them highly attractive for long-term reliability. The shear head design ensures that the connection remains tight, even under vibration, thermal expansion, and other mechanical stresses. This is crucial in high-vibration environments, like power transmission lines exposed to wind, or in areas with fluctuating temperatures.

● No Re-Torquing Required: Traditional mechanical connections might require periodic checks and re-tightening. However, because shear head bolts ensure the proper torque is applied during installation, they generally don’t need maintenance over time.

● Reduced Risk of Oxidation: Properly tightened lugs prevent moisture and air from entering the connection, reducing the risk of oxidation and the subsequent corrosion that can degrade electrical performance.

The shear head bolt provides an extra layer of safety by preventing over-tightening. If a bolt is tightened too much, it can damage the cable or the terminal, leading to potential failure or safety hazards. The shear head’s design ensures that the torque applied is just right, preventing damage and ensuring a secure connection.

Additionally, the shear bolt acts as a visual indicator: once the head shears off, it's a clear sign that the connection is properly tightened. This eliminates guesswork and ensures accuracy, which is particularly important in high-voltage systems.

Cable lugs with shear head bolts are designed to handle the electrical and mechanical stresses of medium-voltage power lines. These lugs are typically made from corrosion-resistant materials such as tinned copper or aluminum, which ensures their durability even in harsh weather conditions.

● Resistant to Environmental Factors: The combination of the robust lug material and the secure shear head bolt design helps resist the impact of environmental factors like moisture, UV exposure, and temperature fluctuations, all of which can lead to electrical failure in less robust systems.

● Vibration Resistance: The shear head bolts prevent the loosening of connections over time, which can be a common issue in power lines subjected to constant wind or mechanical stress.

In the long run, cable lugs with shear head bolts are highly cost-effective. Here's how:

● Reduced Installation Costs: The speed and simplicity of installation reduce labor costs, allowing for faster project completion.

● Fewer Maintenance Needs: Since the connection is made properly the first time, there is no need for regular inspections or maintenance, reducing long-term operational costs.

● Durability: The enhanced longevity of the connection means that replacements or repairs are less frequent, further reducing the overall lifecycle cost.

Cable lugs with shear head bolts are typically designed and manufactured to meet industry standards such as IEC (International Electrotechnical Commission) or ANSI (American National Standards Institute). This ensures that the components are of high quality and are suitable for use in critical power transmission and distribution networks. These standards guarantee that the lugs and bolts perform as expected under the demanding conditions of medium-voltage systems.

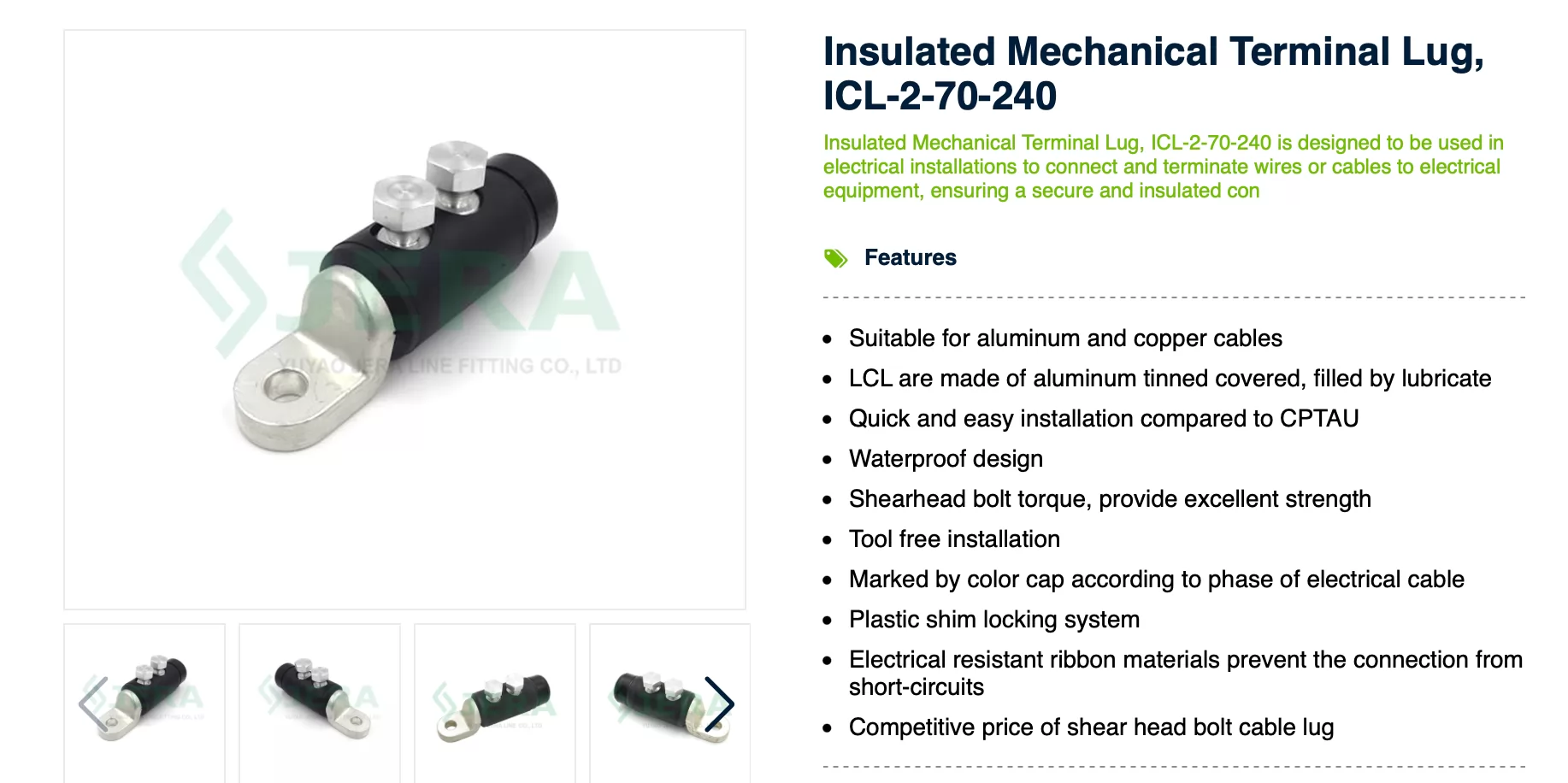

Jera line produce ICL-2-70-240 comply to IEC-61238-1-3, three zones of torque shear bolts,applied with copper and aluminum.

Cable lugs with shear head bolts are particularly well-suited for medium-voltage (1-11kV) power lines, where reliability and durability are of utmost importance. Some common applications include:

● Overhead Power Lines: These lugs provide secure connections in overhead transmission systems that are exposed to environmental elements.

● Underground Power Cables: For underground power distribution, where connections must be secure and resistant to corrosion and environmental stress.

● Substations: Where connections to busbars, transformers, and other equipment require robust and reliable lugs.

Cable lugs with shear head bolts are an indispensable solution in the modern power distribution industry. They offer easy installation, maintenance-free operation, and reliable performance over the long term. Their ability to resist mechanical stress, corrosion, and temperature fluctuations makes them ideal for use in 1-11kV power lines, substations, and other critical infrastructure.

By choosing cable lugs with shear head bolts, utilities and contractors can ensure safety, efficiency, and cost-effectiveness in their power distribution networks, ultimately contributing to a more reliable and resilient electrical grid.