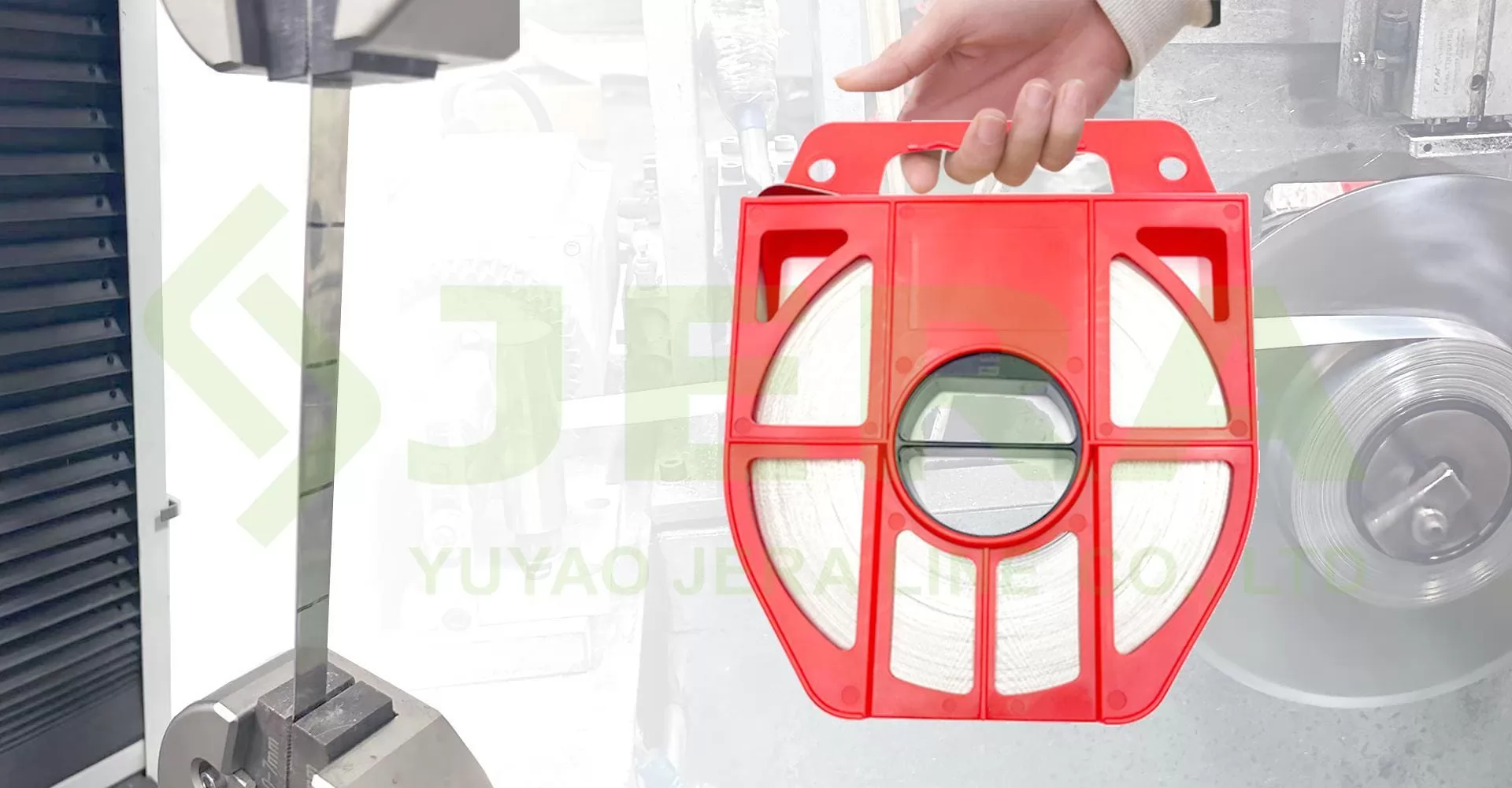

Maximum elongation refers to the point at which a material experiences its highest level of deformation (stretching) before it fractures or breaks. It is a critical mechanical property that provides insights into a material’s ductility, flexibility, and overall behavior under tensile stress. The elongation test is crucial for stainless steel band, buckles, and other overhead line fittings.

1. Sample Preparation:

A standardized sample (often a dog-bone-shaped specimen) is carefully prepared from the material of interest.

The sample dimensions are precisely measured to ensure consistency.

2. Tensile Testing:

The sample is clamped into a testing machine (universal testing machine or tensile testing machine).

An increasing tensile force is applied to the sample until it reaches its breaking point.

During this process, the sample undergoes elongation (stretching).

3. Data Collection:

The maximum force applied to the sample (the breaking force) is recorded.

The elongation (change in length) at the point of fracture is also measured.

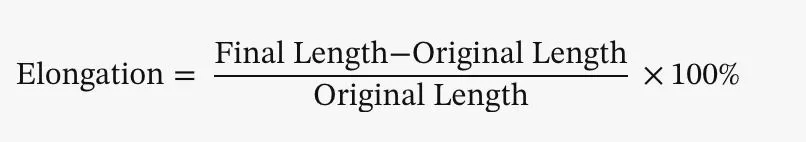

4. Calculating Elongation:

Elongation is expressed as a percentage change in length.

Material Characterization:

Maximum elongation provides valuable information about a material’s ability to withstand stretching forces.

Ductile materials (e.g., metals, certain plastics) exhibit significant elongation before breaking, while brittle materials (e.g., ceramics) have limited elongation.

Product Design and Safety:

Engineers use maximum elongation data to design products with appropriate safety margins.

For example, understanding elongation helps design components like cables, wires, and structural elements.

Quality Control and Standards:

Manufacturers perform maximum elongation tests to ensure product consistency and compliance with industry standards.

Standards organizations (such as ASTM, ISO, and DIN) specify testing procedures and acceptance criteria.

Jera’s Testing Capabilities:

At Jera Line, we conduct maximum elongation tests on various materials used in electrical distribution, telecommunications, and infrastructure.

Our laboratory adheres to international standards, ensuring reliable and high-quality results.

Safety and Reliability:

By understanding maximum elongation, we contribute to the safety and reliability of products used in critical applications.

If you have specific inquiries or need further details, feel free to reach out to us. We’re here to assist you in achieving optimal material performance!