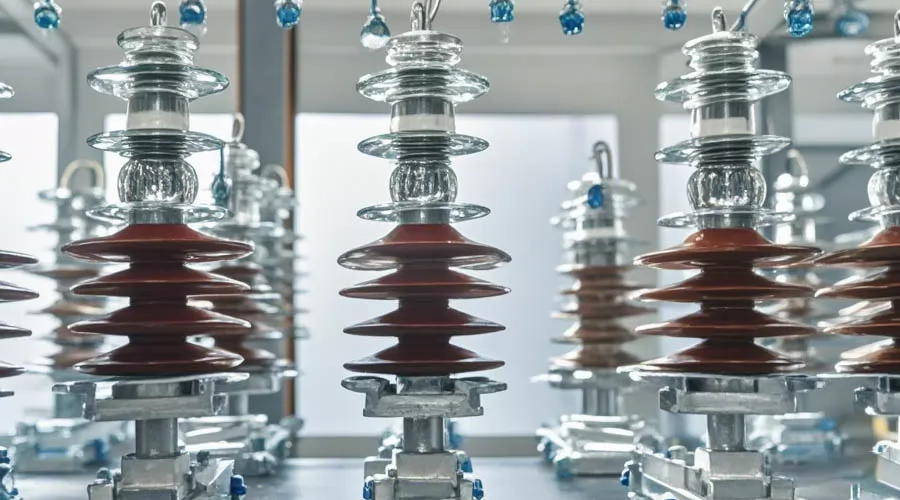

The world of electrical infrastructure is evolving rapidly, with innovation driving the transition to more efficient, cost-effective, and durable materials. Among these advancements is the growing shift from traditional porcelain insulators to polymer insulators. While porcelain insulators have been a staple in power transmission for over a century, polymer insulators are proving to be the better choice in many modern applications.

Polymer Insulators’ adaptability and effectiveness make them a key component in modern industrial applications, offering solutions that traditional materials cannot match.

1. Lightweight and Durable

Polymer insulators are significantly lighter than porcelain counterparts. This weight advantage makes transportation, handling, and installation much easier, reducing overall project costs. Additionally, polymer insulators are more resistant to damage from impact, unlike brittle porcelain.

2. Superior Weather Resistance

Polymer insulators excel in resisting harsh weather conditions, such as extreme temperatures, high humidity, and UV radiation. Their hydrophobic surface minimizes the accumulation of dirt and moisture, reducing the risk of flashover and ensuring reliable performance in polluted environments.

3. Improved Safety

Polymer insulators are made of composite materials, such as fiberglass cores and silicone rubber sheds, which offer excellent electrical insulation and mechanical strength. These materials are non-conductive and reduce the risk of electrical leakage, making them safer for high-voltage applications.

4. Lower Maintenance Requirements

The hydrophobic properties of polymer insulators result in self-cleaning capabilities, minimizing the need for frequent maintenance. This is particularly beneficial in regions with high pollution levels, where porcelain insulators require regular cleaning.

5. Cost-Effectiveness

While the initial cost of polymer insulators may be slightly higher than porcelain, their durability, low maintenance requirements, and longer lifespan make them a more economical choice in the long run.

Polymer insulators are now widely used in:

● Transmission Lines: From low to ultra-high voltage systems.

● Substations: As post insulators and bus-bar supports.

● Railways: For overhead electrification systems.

● Switchgear and Transformers: Offering lightweight and compact insulation solutions.

Jera Line has established itself as a trusted manufacturer and supplier of polymer insulators, offering solutions tailored to meet the demands of modern electrical infrastructure.

1. Comprehensive Manufacturing Expertise

Jera Line has extensive experience with R&D department in designing and producing high-quality polymer insulators.

2. Superior Quality Assurance

Our products undergo rigorous testing in Jera Line’s own factory laboratory to ensure durability, reliability, and safety. Key tests include:

● Tensile Strength Testing

● Aging and UV Resistance Testing

● Electrical Insulation Testing

● Mechanical Load Testing

3. Customizable Solutions

At Jera Line, we understand that every project has unique requirements. We offer a variety of polymer insulators, which suitable for your projects, they can be customized in terms of size, voltage range, and mechanical load capacities.

Besides, we also provide customized stickers on carton boxes.

4. Global Standards Compliance

Jera Line’s polymer insulators are designed to meet the diverse needs of global markets. Our products comply with international standards, ensuring compatibility with a wide range of transmission and distribution systems worldwide.

The transition from porcelain to polymer insulators reflects the power industry's commitment to adopting innovative solutions that enhance efficiency, reliability, and sustainability. As polymer insulators continue to evolve, they are set to become the standard choice for modern electrical infrastructure.

Choosing the right polymer insulator supplier can make a significant difference in the performance and reliability of your electrical infrastructure.

Contact us today to discuss your project needs and discover how Jera Line can support your goals with advanced polymer insulator solutions.