Based on the principle of quick production, Jera Line improves the efficiency of the production process, ensuring that team members can concentrate and work together, maintain discipline and flexibility, change the production processes according to the actual situation, and respond to the needs of customers and the market.

We follow the batch order production method, which requests us to have the most effective production operations – quick, as well as decreasing the time between each operation change.

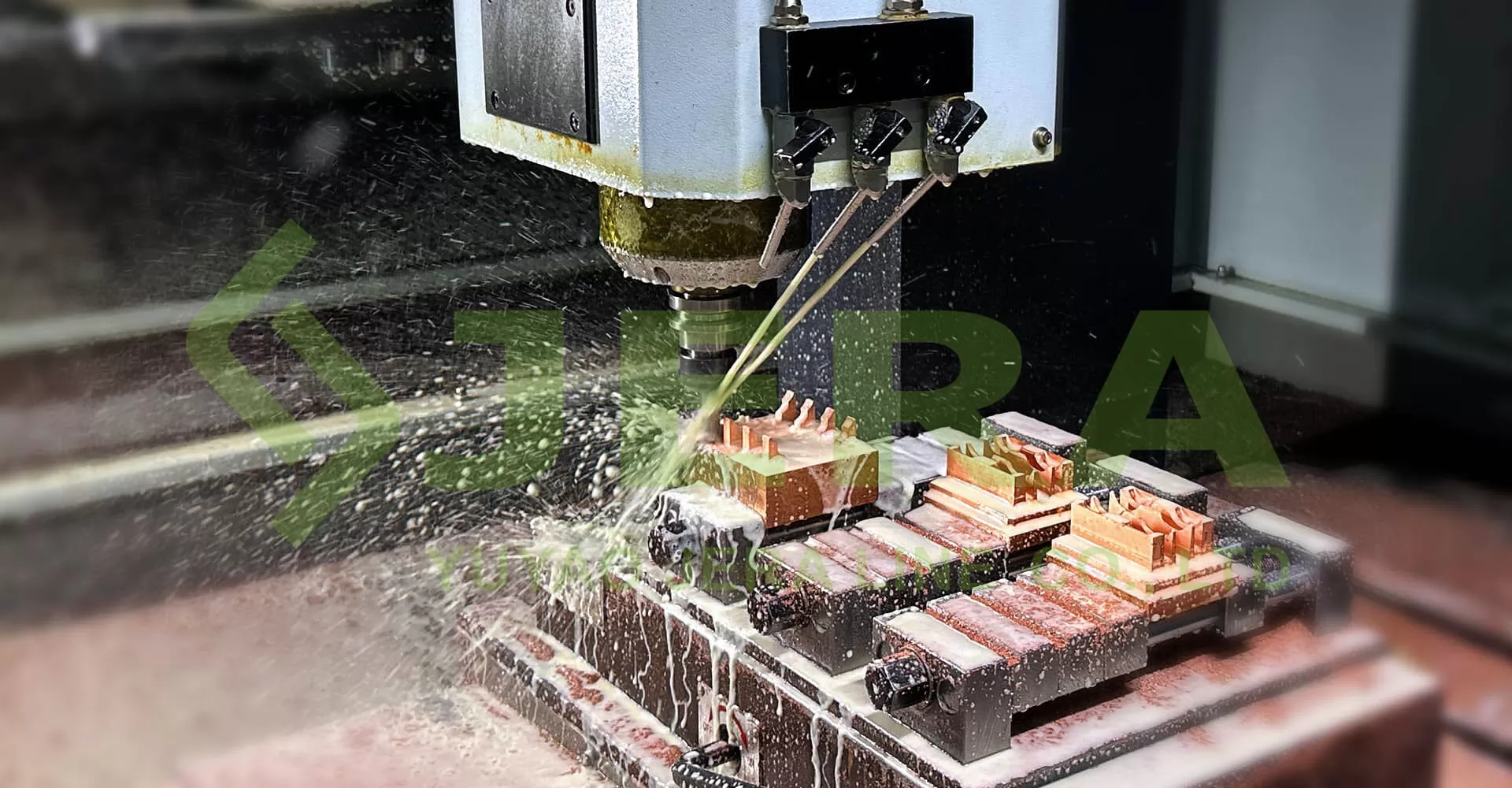

95% of our production abilities are gathered at one site, so the different production technologies combined in one core single process, guarantee high production performance and quick speed for orders. You may find more details about our Diverse technologies gathered by one facility here.

We use some lean and TPS ways to reach the possible efficiency. As well as ERP digital systems, bar codes, etc.

Also, we implement some DMAIC problem-solving system as well as planning system, such as:

• Daily planning is one of the key tools in production management. It is not only a task assignment plan but also a means of detection. Production managers arrange production orders based on priority and keep records every day. By comparing production capacity through daily records, we can identify where problems exist and further optimize. Daily planning allows us to quantify anomalies, and promptly identify and solve problems.

• Daily material preparation corresponds to daily planning. It includes not only materials but also other production resources, such as equipment, drawings, personnel, etc. Without material preparation, problems will occur during the production process, wasting time and reducing efficiency. Daily material preparation is divided into large, medium, and small preparations to ensure no abnormalities in materials.

• Some problems cannot be detected by daily planning and material preparation. At this time, we need to carry out daily coordination. For problems that arise temporarily, immediate measures and decisions are needed, and department heads communicate directly to come up with solutions. This method reduces unnecessary intermediate processes, greatly reducing stagnation, rework, and other issues in factory production.

Jera factory constantly improves cooperation among various departments, improves cooperation among various departments. Due to the cost of delivery, preparation fees, production costs, delivery costs, packaging costs, and prior planning, we will make every effort to ensure quick production speed.

Welcome to click our video link to learn more about our factory.