An insulation-piercing connector (IPC) is a specialized electrical component designed to create a secure and reliable connection by penetrating the insulation of a wire without the need for stripping. This innovative design ensures a seamless electrical link while preserving the insulation's integrity.

These connectors are widely utilized in various industries, including power distribution, telecommunications, and automotive systems. Their robust construction and ability to maintain insulation protection make them an essential solution for ensuring durable and efficient electrical connections in demanding environments.

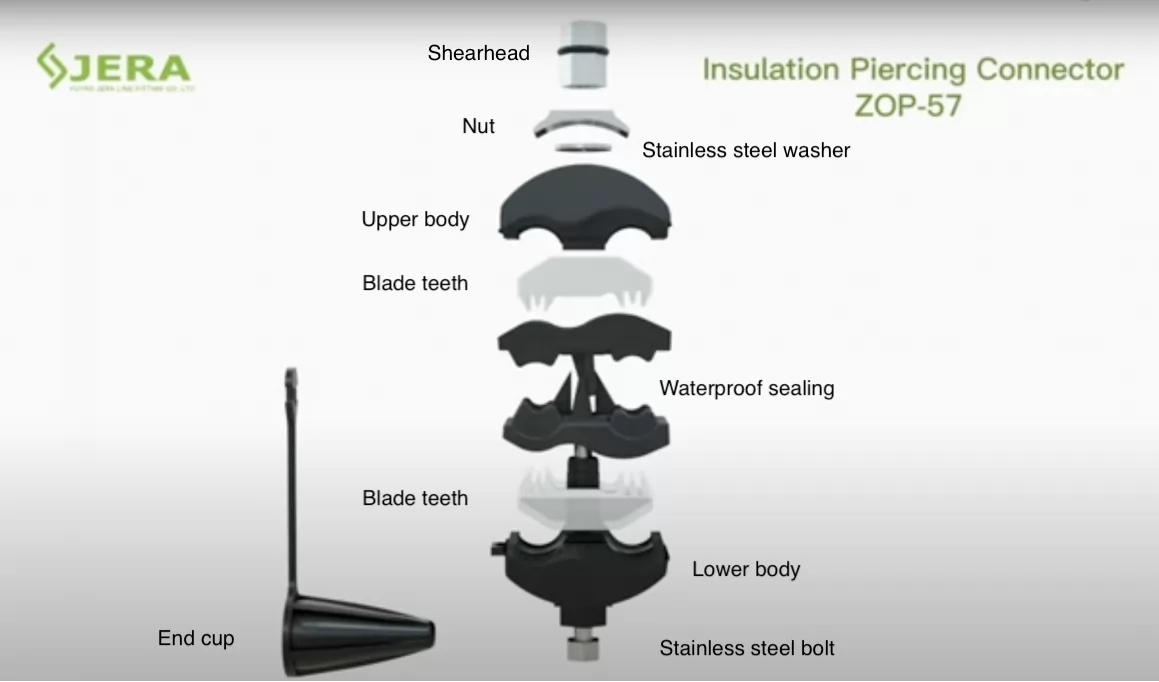

An insulation-piercing connector (IPC) is composed of multiple components that work synergistically to establish a reliable electrical connection while preserving the wire's insulation.

Key components of JERA LINE insulation tap connectors include:

These elements are designed to form a secure and durable connection without the need to strip insulation. This feature is particularly beneficial in applications where insulation integrity is critical.

Insulation-piercing connectors are versatile and find use in various electrical applications, such as:

Power Distribution:

Telecommunications:

Street Lighting:

Automotive Systems:

Industrial Applications:

This broad range of applications highlights the connector's adaptability and reliability across industries.

Insulation-piercing connectors (IPCs) offer numerous benefits, making them an efficient and versatile solution in various electrical applications:

Time-Saving Installation

Reliable Connections

Waterproof Design

Versatility

Enhanced Safety

Space-Saving

Cost-Effective

Durability

Key installation steps:

-- Insert the branch cable in the connector as shown.

-- Insert the main cable. Put on the cable end cap

-- Gradually tighten the nut, until it shears off.

Testing insulation-piercing connectors (IPCs) involves conducting a series of rigorous evaluations to ensure their performance, safety, and compliance with industry standards. These tests are categorized as type tests and routine tests:

Type tests assess IPCs under various conditions to validate their suitability for specific applications. These include:

JERA ENERGY’s ZOP Series IPCs have passed the NFC 33-020 type tests, certified by an EU-independent laboratory.

1.The NFC 33-020 standard is a French standard that specifies the requirements for insulation piercing connectors (IPCs) used in low-voltage electrical installations. The standard covers the design, materials, testing, and performance of IPCs, as well as the requirements for installation and use.

2.The NFC-33020 standard defines the characteristics of IPCs, including their size, shape, and piercing depth, as well as their electrical and mechanical properties. It also specifies the tests that IPCs must undergo to ensure their compliance with the standard, including tests for electrical resistance, mechanical strength, and environmental resistance.

3.The standard also provides guidelines for the installation and use of IPCs, including the recommended torque values for fasteners, the minimum and maximum wire sizes that can be used with the connector, and the maximum current-carrying capacity of the connector.

Routine tests for insulation piercing connectors (IPCs) are conducted to ensure the quality, safety, and performance of the connectors before they are put into service. These tests are typically carried out during the manufacturing process and may include the following:

Jera Line has own factory laboratory with test equipment and measuring tools, to ensure our insulation piercing connectors meet the required standards and specifications for quality, safety, and performance before they are installed in electrical systems.

JERA Energy provides a comprehensive range of overhead cable tap connectors for 1KV power lines, including the ZOP series insulation piercing connectors.

Learn more about our products here.

Jera Line established from 2012, produces the insulation piercing connectors from year 2015, and have experience in many international projects.

Here are some factors that why JERA is one of the best manufacturers and why to purchase IPCs from Jera Energy:

We hope you enjoyed our guide to Insulation piercing connectors. We are direct factory and will be happy to answer on any commercial inquires related to our product range.

Feel free to send us an email or call, and our team of professionals will assist you.