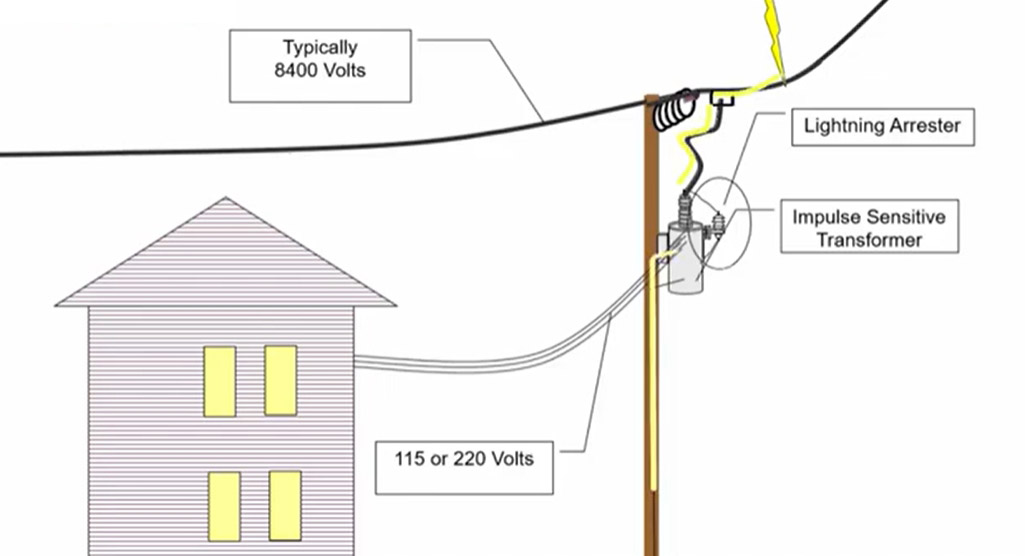

Metal Oxide Varistors (MOVs) are essential components in electrical systems, designed to protect sensitive equipment from damaging voltage surges. These devices operate on a simple yet effective principle: they exhibit high resistance under normal voltage conditions but rapidly decrease their resistance when exposed to high-voltage transients. This allows them to divert excess energy away from the protected equipment, safeguarding it from potential damage.

How Does a Metal Oxide Varistor (MOV) Surge Arrester Work?

● Normal Operation: Under normal operating conditions, the MOV presents a high impedance, allowing only a minimal amount of current to flow through it.

● Surge Event: When a voltage surge occurs, the MOV's resistance decreases dramatically, allowing it to conduct the excess energy to ground.

● Energy Dissipation: The MOV absorbs the surge energy and dissipates it as heat, protecting the connected equipment.

Key Components of an MOV Surge Arrester

An MOV surge arrester consists of several critical components that work together to safeguard your electrical systems:

● Metal Oxide Varistor Disk: The core component, made of zinc oxide and other metal oxides, which exhibits nonlinear voltage-current characteristics.

● Electrodes: Conductors that connect the MOV disk to the external circuit.

● Encapsulation: A protective housing that encloses the MOV disk and electrodes, shielding them from environmental factors.

● Terminals: Connect the surge arrester to the electrical system.

Jera Line, a direct factory located in China produce MOV Surge Arrester: SA-0.2810

SA-0.2810 is under R&D by Jera Line, it’s a high-performance MOV surge arrester designed to protect electrical systems from voltage surges.

Key features include:

● Overvoltage and Undervoltage Protection: Safeguards equipment from both high and low voltage events.

● Reduced Maintenance: Minimal maintenance requirements, ensuring long-term reliability.

● Enhanced System Reliability: Protects critical components and minimizes downtime.

● Compact Design: Easy to install and integrate into various electrical systems.

Why IPCs are the Best Solution for LV Surge Arrester Attachment?

Rapid and Efficient Installation: No cable stripping required and tool-free installation

Reliable and Durable Connections: IPCs create a reliable and secure connection between the surge arrester and the cable, ensuring optimal performance.

Weather Resistance: Designed to withstand harsh environmental conditions, including extreme temperatures, humidity, and UV radiation.

Long-lasting Performance: IPCs are built to last, providing long-term reliability.

Non-Destructive Installation: IPCs do not damage the cable insulation, minimizing the risk of future failures.

Protection Against Water Ingress: The sealed connection provided by IPCs prevents water ingress, which can lead to corrosion and degradation.

Reduced Labor Costs: The quick and easy installation process lowers labor costs.

Minimized Material Costs: Less material is required compared to traditional connection methods.

Jera Line's IPCs: A Reliable Solution

Jera Line offers a range of high-quality IPCs specifically designed for surge arrester applications. Our ZOP series, including the ZOP-23 and ZOP-30 models, offer the following benefits:

● Easy Installation: Simple and efficient installation process.

● Reliable Performance: Ensures secure and long-lasting connections.

● Weather Resistance: Designed to withstand harsh environmental conditions.

● Durability: Built to last, providing long-term reliability.

● Safety and Compliance: Meets international safety standards.

Welcome to contact Jera Line to find more products and solutions for your electrical infrastructure needs!