Jera Line laboratory is capable to conduct the environmental ageing test of outdoor products by related equipment to guarantee the corrosion resistance criteria of:

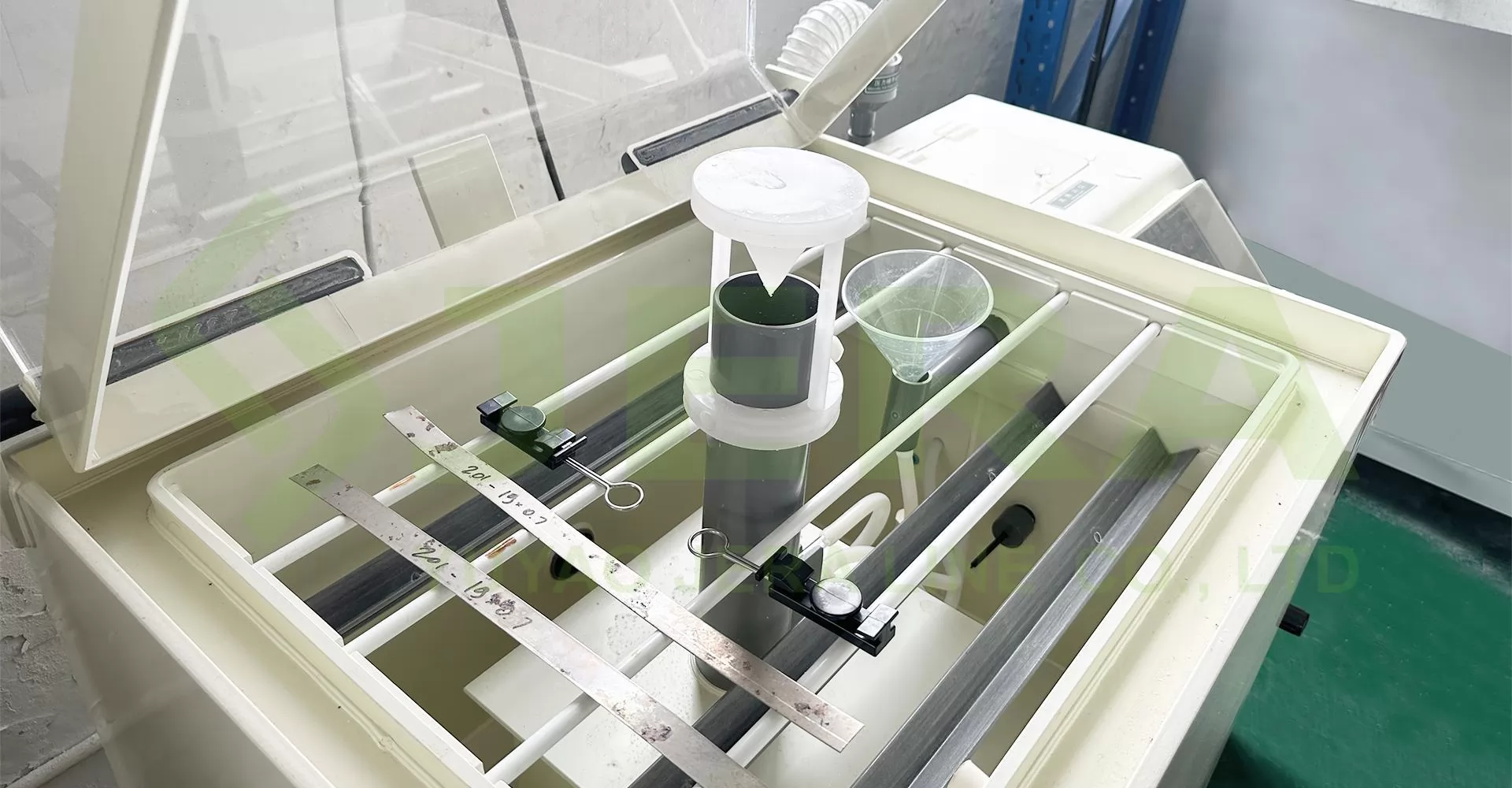

This test presents briefly the test of steel parts applied in the product. Before the test, a visual inspection of the samples was preformed to verify that there were no defects or damages that could affect its performance. The samples was then conditioned at a room temperature for twenty-four hours. All metal parts of the samples were subjected to the salt spray test according to the below conditions. The product is to verify the resistance to the deterioration produced by saline spraying and to evaluate the quality and uniformity of the materials submitted to the test. The samples was exposed for 10 days at a temperature of 35C, and sprayed during this period with a saline solution. The solution was prepared by dissolving 5% mass of sodium chloride in 95% mass of distilled waster. The pH value of the solution was measure and controlled, the valued recorded during the test run are within the specific limits.

After the test, the samples are subjected to a visual examination and not traces of corrosion are to be observed.

At the end of test the samples showed no traces of corrosion.

We serve customers worldwide and some countries have variety of humidity and temperatures, have continuous rainfall and high humidity just like the South Asia. By the salt mist test we ensure that our products can be applied in different weather conditions and this test can be a good examination for products performance.

Welcome to contact us for further information.