An insulation piercing connector is a type of electrical connector that is designed to pierce through the insulation of an electrical wire in order to make a secure and reliable electrical connection.

Insulation piercing connectors are often used in electrical distribution and power transmission systems, as well as in telecommunications and automotive applications. They are designed to provide a strong and durable connection while also maintaining the integrity of the insulation around the wire.

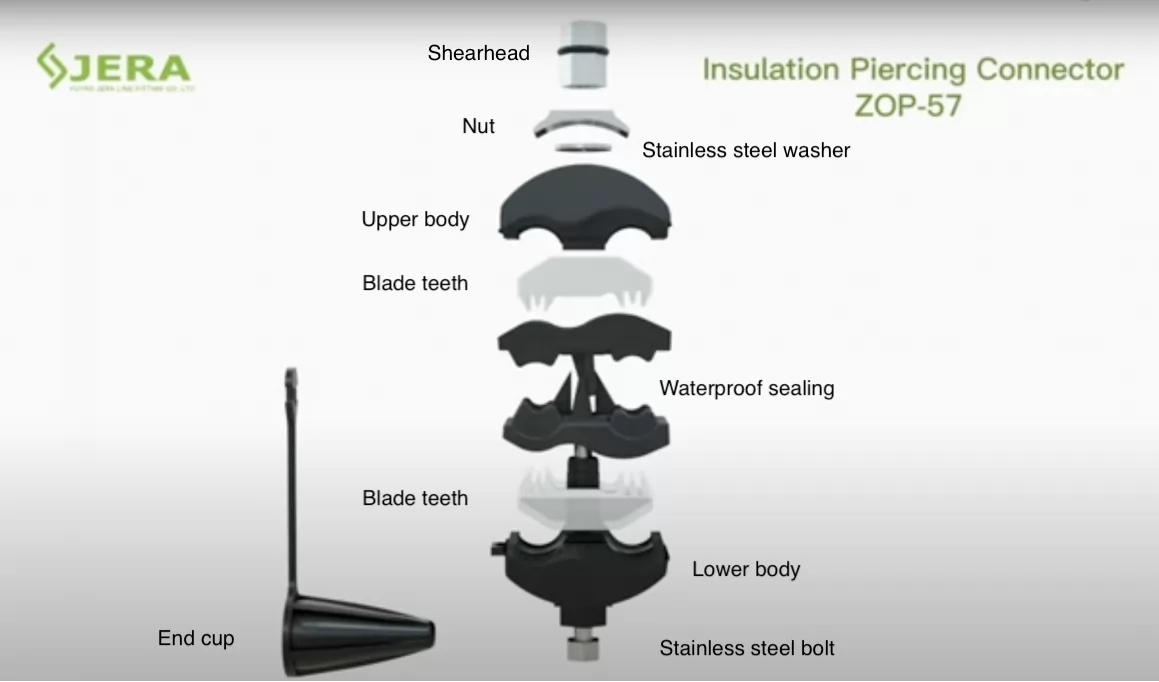

An insulation piercing connector (IPC) typically consists of several components that work together to create a reliable and secure electrical connection.

JERA LINE insulation tap connectors’ components include:

Shearhead-- Nut-- Stainless steel washer -- Upper body -- Blade teeth -- waterproof sealing -- lower body -- Stainless steel bolt -- End cap

These components work together to create a robust and reliable electrical connection without the need for stripping the insulation from the wires, making IPCs particularly useful in applications where maintaining the integrity of the insulation is essential.

Where is insulation piercing connector used?

Insulation piercing connectors (IPC) are used in a variety of electrical applications, including:

Power distribution: IPCs are commonly used to connect and splice electrical wires in power distribution systems. They are used to connect overhead power lines, underground cables, and transformers.

Telecommunications: IPCs are used in telecommunications systems to splice and connect telephone wires, fiber optic cables, and coaxial cables. They are commonly used in telephone distribution boxes and junction boxes.

Street lighting: IPCs are used in street lighting systems to connect and splice electrical wires. They are commonly used in street light poles and junction boxes.

Automotive: IPCs are used in the automotive industry to connect and splice electrical wires in vehicles. They are commonly used in wiring harnesses, battery connections, and electrical sensors.

Industrial: IPCs are used in industrial applications to connect and splice electrical wires in machines and equipment. They are commonly used in motor control centers, switchgear, and control panels.

The use of insulation piercing connectors (IPCs) offers several advantages in electrical applications, including:

Time-saving: IPCs eliminate the need to strip insulation from wires, saving time during installation and maintenance.

Reliable connection: IPCs provide a secure and reliable electrical connection without the risk of wire damage or loose connections.

Waterproofing: JERA ENERGY IPCs are designed to provide a waterproof seal, making them suitable for outdoor and underground applications.

Versatility: IPCs can be used with a wide range of wire sizes and types, offering flexibility in various electrical installations.

Reduced risk of injury: IPCs minimize the risk of electric shock and injury during installation due to their insulation-piercing design.

Space-saving: IPCs are compact and can be used in tight spaces, making them suitable for applications with limited room for connections.

Cost-effective: IPCs can reduce material and labor costs by simplifying the installation process and minimizing the need for additional components.

Durability: Many IPCs are designed to withstand harsh environmental conditions, ensuring long-term reliability in outdoor and industrial settings.

Key installation steps:

-- Insert the branch cable in the connector as shown.

-- Insert the main cable. Put on the cable end cap

-- Gradually tighten the nut, until it shears off.

Type tests for insulation piercing connectors (IPCs) are conducted to validate the performance, safety, and compliance of the connectors with relevant standards and specifications.

These tests are typically carried out on representative samples of the IPCs and may include the following:

JERA ENERGY ZOP series Insulation piercing connector got NFC 33-020 type test report from EU independent laboratory.

What is NFC 33-020 standard for Insulation piercing connector?

1.The NFC 33-020 standard is a French standard that specifies the requirements for insulation piercing connectors (IPCs) used in low-voltage electrical installations. The standard covers the design, materials, testing, and performance of IPCs, as well as the requirements for installation and use.

2.The NFC-33020 standard defines the characteristics of IPCs, including their size, shape, and piercing depth, as well as their electrical and mechanical properties. It also specifies the tests that IPCs must undergo to ensure their compliance with the standard, including tests for electrical resistance, mechanical strength, and environmental resistance.

3.The standard also provides guidelines for the installation and use of IPCs, including the recommended torque values for fasteners, the minimum and maximum wire sizes that can be used with the connector, and the maximum current-carrying capacity of the connector.

What’s Routine test for Insulation piercing connector?

Routine tests for insulation piercing connectors (IPCs) are conducted to ensure the quality, safety, and performance of the connectors before they are put into service. These tests are typically carried out during the manufacturing process and may include the following:

-- Visual inspection test

-- Test of permanent marking

-- Dielectrical voltage test in water

-- Shear head functions test

Jera Line has own factory laboratory with test equipment and measuring tools, to ensure our insulation piercing connectors meet the required standards and specifications for quality, safety, and performance before they are installed in electrical systems.

Why Jera-energy.com is one of the best manufacturers of insulation piercing connectors and why to purchase insulation piercing connectors from JERA?

Jera Line established from 2012, produces the insulation piercing connectors from year 2015, and have experience in many international projects.

Here are some factors that why JERA is one of the best manufacturers and why to purchase IPCs from Jera Energy:

Product Quality and Reliability: Jera Energy produces high-quality insulation piercing connectors that are reliable, durable.

Compliance and Certification: Jera Energy ensures insulation piercing connetors comply with relevant inductry standards, such as NFC 33-020, EN-50483,providing customers with confidence in the quality and safety of the products.

Range of Offerings: Jera Energy offers a diverse range of insulation piercing connectors for 1kv power lines, to meet various application requirements

Research and Development: Jera Energy invests in research and development to continually improve the design, performance, and reliability of their insulation piercing connectors, ensuring they remain competitive in the market.

Customer Support: Jera Energy provides strong customer support, including technical assistance, flexible OEM with stickers , and after-sales service, which can be important for customers seeking reliable solutions for their applications.

Competitive price: Jera Line located in a small city in Yuyao Ningbo, scale production facility casued the competitive price.

We hope you enjoyed our guide to Insulation piercing connectors. We are direct factory and will be happy to answer on any commercial inquires related to our product range.

Feel free to send us an email or call, and our team of professionals will assist you.