_1731117993_WNo_1600d900.webp)

We’re thrilled to see your interest in pigtail screws! Our guide is here to be your perfect companion in discovering the magic of this little component. We’ll take you through everything—how pigtail screws work, their unique design, and how to use them effectively. From installation and maintenance to troubleshooting, we’ll be with you every step of the way, helping you master each aspect of pigtail screws. Finally, we’ll share some expert tips on choosing the right manufacturer, so you can find the perfect products to meet your needs.

| Table of Contents |

|---|

|

3. Benefits of Using Pigtail Screws 4. Applications of Pigtail Screws 5. How to Install a Pigtail Screw 6.1 Product File 7. Maintenance Tips for Pigtail Screws 8. Conclusion |

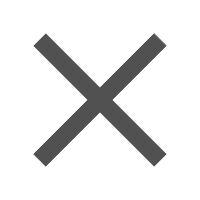

Pigtail Screw is a screw that usually has a unique spiral or curved design, similar to the shape of a pig's tail (hence the name "Pigtail"). This design allows it to better connect tightly to the target object during installation and enhance stability. Its threads can easily cut into the material and provide a strong grip. It is widely used to connect wires, fix parts or fix other structural parts.

Pigtail Screw can be a standard metal screw or made of stainless steel or other alloys as required, which has corrosion and oxidation resistance.

There are many types of Pigtail Screws, each type can be selected according to different uses and requirements. Here are some common types:

Each type of Pigtail Screw has its specific advantages, and the appropriate material and size should be selected according to the needs.

There are many benefits to using Pigtail Screws, including:

Pigtail Screws are widely used in many fields. Here are some typical application scenarios:

To install the Pigtail Screw, you can follow these steps:

1. Prepare the Tools

Make sure to use the appropriate screwdriver or power tool, and check that the size of the Pigtail Screw matches the target material.

2. Locate the Installation Position

Mark the installation position of the screw according to the part or material that needs to be fixed.

3. Screw in the Screw

Use a screwdriver or power tool to screw the Pigtail Screw into the material. Due to its spiral design, it will naturally cut in and fix tightly.

4. Check the Fixing Effect

Make sure the screw is fully screwed in and check whether the connection is firm and reliable.

During the installation process, avoid excessive force to avoid damaging the material or excessive wear of the screw.

When purchasing a Pigtail Screw, you need to consider the following factors:

One of the top choices in the market for high-quality Pigtail Screw is Jera Line, a leading manufacturer known for its premium, precision-engineered screws.

Jera Line is a trusted name in the industry, offering high-quality products and services that are specifically designed to meet the unique needs of our clients.

Here are several reasons why Jera Line should be your preferred partner:

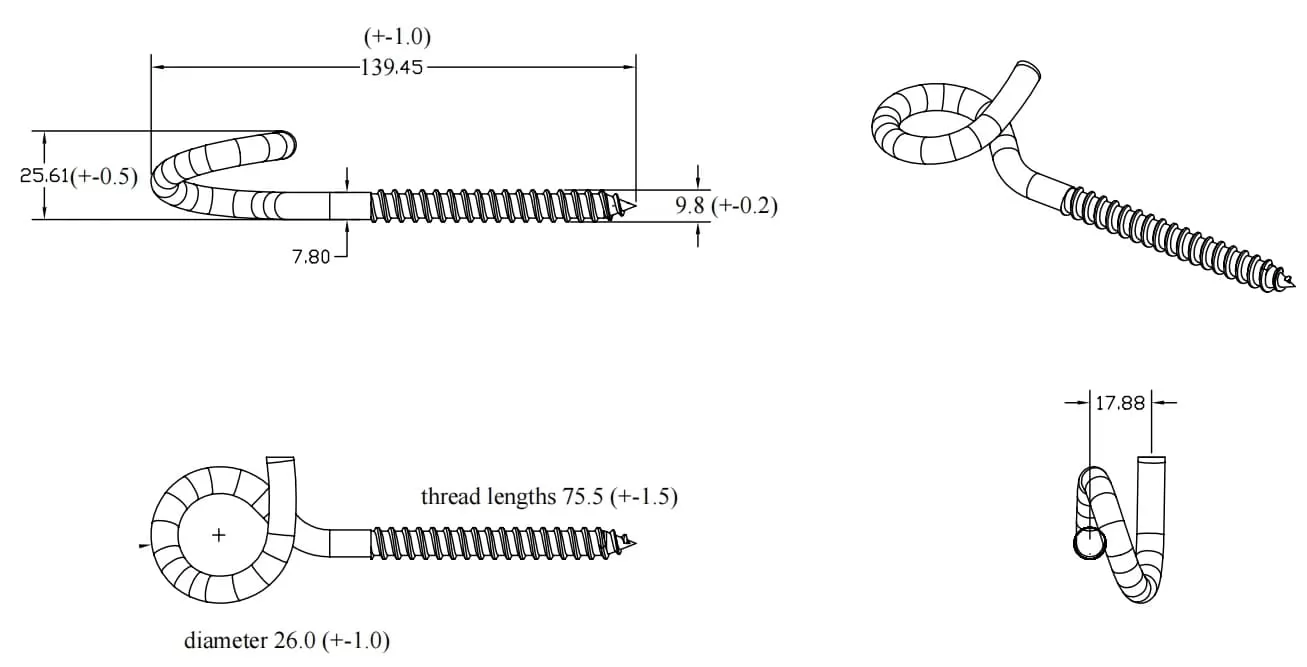

Pigtail screw PS-8, either called pig tail hook is a pigtail shape screw installed on wooden poles or wooden surfaces as a hook to tension low voltage anchor bracket and ABC cable during electrical li

S caffolding, construction and so on

| Code | MBL, kN | Length,mm | Material |

|---|---|---|---|

| PB-8 | 2 | 140/75 | Galvanized Steel |

Pigtail eye screw is made of high quality carbon steel, surface plating can be choose hot dip galvanized or cold galvanized upon requirements. Galvanized finish surface extend the service life during various weather conditions.

Pig tail eye bolt applied on main or end use electrical connections, up to 1KV on dead end or intermediate routes with tension or suspension clamps. To install the pigtail screw all you need is to secure it on the pole as a screw, and then attach an appropriate LV ABC clamp, helps to secure cable as tightly as possible to pole or wooden surface.

To extend the life of your Pigtail Screw and maintain its good performance, you can follow these maintenance recommendations:

Keep the screws and their connection areas dry to avoid moisture accumulation that causes corrosion.

As a unique and powerful connection tool, Pigtail screw has a wide range of applications and significant advantages. From electrical installation to mechanical connection, it can provide reliable and durable solutions. When selecting and using pigtail screw, make sure to purchase it reasonably according to application requirements, materials, sizes, etc., and perform regular maintenance to ensure its long-term and stable use effect.

If you have more questions or needs about pigtail screw, please contact us for more professional advice.

Click here to get a free consultation.